Precision Cutting for Irregular Geometries with 5 Axis Lasers

Key Takeaways

- Difficulties Encountered in Shaping Uneven Forms

- Safety Measures for Utilizing 5 Axis Lasers

- Financial Assessment of Implementing 5 Axis Laser Cutting

- Improving Productivity with 5 Axis Lasers

Common Challenges in Cutting Irregular Geometries

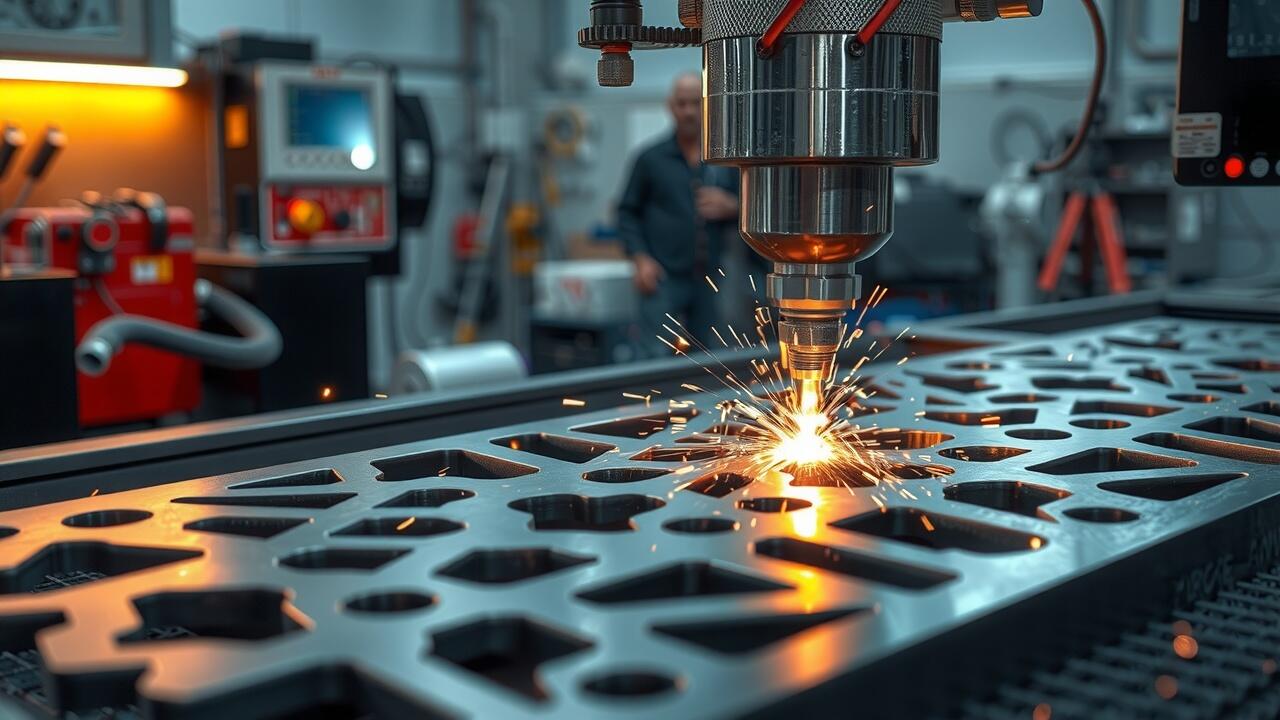

Cutting irregular geometries presents a unique set of challenges that require specialized equipment and expertise. Traditional cutting methods may struggle with precision and consistency when faced with complex shapes. For instance, achieving clean edges on materials like titanium or carbon fiber demands not only precision but also the ability to adjust cutting angles dynamically. This is where 5 axis laser cutting excels, as it allows for intricate adjustments and can tackle geometrical complexities with ease. Without proper capabilities, manufacturers risk producing inaccurate cuts, which can lead to increased waste and higher production costs.

Furthermore, the types of materials often encountered in irregular shapes can exacerbate difficulties in cutting processes. Certain metals may require varying speeds and power settings to achieve optimal results, while softer materials like plastics may melt or warp if not handled correctly. Utilizing 5 axis laser cutting services near me enables manufacturers to employ advanced techniques, enhancing their ability to manage diverse material properties. Companies need to invest in training staff and adopting best practices to effectively navigate these challenges and maximize their laser cutting systems’ capabilities. Maintaining an ongoing evaluation of performance metrics can lead to continual improvement in efficiency and product quality.

How Can These Challenges Be Overcome with Advanced Techniques?

Advanced techniques such as adaptive control systems significantly enhance the efficacy of 5 axis laser cutting operations when addressing irregular geometries. These systems adjust parameters in real-time, optimizing speed and power based on material conditions. For instance, when working with materials that have varying thicknesses or textures, real-time feedback allows the laser to maintain consistent quality throughout the cut. Moreover, software solutions that integrate design and cutting processes can streamline the workflow, reducing the time required to transition from design models to production.

Another approach involves utilizing precise beam delivery methods, such as fiber laser technology, which can improve cut quality on complex shapes. A case study involving aerospace components revealed a 30% reduction in scrap material when transitioning to a 5 axis laser system with sophisticated beam manipulation capabilities. Coupled with high-resolution optics, these advancements allow operators to achieve intricate designs without sacrificing efficiency. Companies offering 5 axis laser cutting services near me are increasingly investing in these technologies to not only meet stringent industry standards but also to deliver superior results that drive competitiveness in the market.

Safety Protocols When Operating 5 Axis Lasers

Ensuring safety during 5 axis laser cutting operations is paramount to prevent accidents and injuries. Operators must wear appropriate personal protective equipment (PPE), including safety goggles designed to filter harmful laser wavelengths. Additionally, implementing a laser safety zone with restricted access can help minimize the risk of unintended exposure while cutting complex geometries. Regular training sessions can ensure that all employees understand the risks associated with operating 5 axis laser systems. For instance, OSHA standards mandate that operators receive safety training specific to laser equipment usage.

Furthermore, proper maintenance of the 5 axis laser is essential for both performance and safety. Routine checks on the laser's protective housing and emergency shut-off mechanisms help identify any potential hazards before they escalate. A monitoring system that alerts operators to malfunctions can serve as an additional layer of safety. Companies utilizing 5 axis laser cutting services near me often find that adherence to safety protocols not only meets regulatory compliance but also enhances workplace morale and productivity. Regular audits of safety practices ensure that the cutting environment remains secure and efficient.

What Safety Measures Should Be Implemented?

Implementing effective safety measures is essential when operating 5 axis lasers, particularly in environments where irregular geometries are commonplace. Adequate training for operators can significantly reduce the risk of accidents. This includes thorough understanding of machine functionality, along with familiarity with materials and cutting techniques specific to 5 axis laser cutting. Operating procedures should align with OSHA standards and incorporate risk assessments tailored to specific tasks. Personal protective equipment (PPE) such as laser safety glasses, gloves, and protective clothing must be readily available to all personnel working in proximity to the machines.

Additionally, regular maintenance of the 5 axis laser systems is a key preventative measure. Establishing a routine inspection schedule ensures that all safety features are operational. Maintenance records should document inspections, repairs, and part replacements, helping to identify any recurring issues. Installing safety interlocks and emergency shut-off buttons can further enhance operator protection during unforeseen circumstances. Training staff to respond effectively to emergencies can mean the difference between a quick resolution and a significant incident, reinforcing the importance of a culture of safety within organizations utilizing 5 axis laser cutting services.

Cost Analysis of Adopting 5 Axis Laser Cutting

Investing in 5 axis laser cutting technology can initially seem daunting, but long-term gains often offset the upfront costs. A study by the Fabricators & Manufacturers Association found that shops using advanced laser technology reported a 25% reduction in material waste. These savings arise not only from precise cuts but also from the ability to handle complex designs more efficiently. For instance, a manufacturer recently transitioned to 5 axis laser cutting and increased production speed by 40%, allowing them to take on more projects and significantly boost revenue.

To further justify investment in these services, companies should consider the operational expenses associated with traditional cutting methods. Conventional techniques often require multiple setups and longer processing times, leading to higher labor costs. In contrast, 5 axis laser cutting enables a streamlined workflow, reducing reliance on manual labor and minimizing the risk of human error. Companies searching for "5 axis laser cutting services near me" might find that local providers offer competitive pricing structures that enhance value while ensuring compliance with industry standards. Embracing this technology can lead to a better return on investment in the long run.

How Can Companies Justify the Investment in This Technology?

Investing in 5 axis laser cutting technology can yield substantial returns for companies specializing in intricate components. Consider an aerospace manufacturer that increased production efficiency by 40% after implementing 5 axis laser capabilities. With reduced waste and improved operational speed, they were able to cut down the average processing time from six hours to four hours per part. This enhancement not only increases throughput but also enhances competitiveness in a market that demands precision and versatility.

Moreover, the cost savings associated with 5 axis laser cutting extend beyond immediate production metrics. A study by the Fabricators & Manufacturers Association highlighted that organizations utilizing advanced laser cutting services typically experience a 30% reduction in labor costs due to automated processes. Industry leaders are also recognizing that higher-quality cuts lead to less post-processing work, translating into further savings. Companies seeking to meet precise tolerances in sectors like automotive or medical device manufacturing are finding that the return on investment justifies the technology's initial costs. Implementing these technologies ensures alignment with industry standards while pushing the boundaries of innovation.

- Improved production efficiency can lead to increased profitability.

- The reduction in waste contributes to more sustainable manufacturing practices.

- Enhanced speed in production helps companies respond quickly to market demands.

- Higher quality cuts reduce the need for rework and post-processing efforts.

- Automation can lead to a safer work environment by minimizing human error.

- Investing in advanced technology can provide a competitive edge in the marketplace.

- Adopting modern practices aligns with the broader trend towards Industry 4.0 and digital transformation.

Enhancing Workflow Efficiency with 5 Axis Lasers

Efficiency in manufacturing processes directly influences overall productivity. Implementing 5 axis laser cutting technology can substantially enhance workflow by enabling rapid execution of complex designs. For instance, a company utilizing this technology may cut intricate parts 30% faster compared to traditional methods. The ability to program various angles and positions streamlines production, minimizes downtime, and reduces the setup time required for multiple operations.

Automation also plays a critical role in optimizing efficiency within the production line. Integrating software systems with 5 axis lasers allows for real-time adjustments and monitoring, ensuring accuracy and minimizing waste. A case study from the aerospace industry demonstrated a 25% reduction in material waste through precise cutting techniques offered by 5 axis laser cutting services. By eliminating redundancies and maximizing material usage, manufacturers can see significant cost savings while also increasing their output capacities.

FAQS

What are the main challenges in cutting irregular geometries with lasers?

The main challenges include achieving precision in complex shapes, managing material waste, and addressing potential thermal distortion that can occur during the cutting process.

How can advanced techniques help overcome these challenges?

Advanced techniques, such as optimized beam control and software integration for real-time adjustments, can enhance accuracy, reduce waste, and improve the overall cutting quality when dealing with irregular geometries.

What safety protocols should be followed when operating 5 axis lasers?

Operators should wear appropriate personal protective equipment (PPE), ensure proper ventilation, use safety interlocks, and follow manufacturer guidelines to minimize risks associated with laser operation.

Is investing in 5 axis laser cutting technology cost-effective for businesses?

Yes, companies can justify the investment by considering long-term savings through reduced material waste, increased production efficiency, and the ability to take on more complex projects that require precision cutting.

How can 5 axis lasers enhance workflow efficiency in manufacturing?

5 axis lasers can streamline the cutting process by allowing for continuous operation, reducing setup times, and enabling the cutting of multiple complex parts in a single pass, thus improving overall productivity.